Proprietary Services

We design and manufacture our own range of tooling and consumables, various sizes and materials for locks, reinforcement pins, stitching pins, sealing pins, high-temperature resistant pins, and thread replacement inserts. We have developed various written procedures for the repair and restoration techniques and processes for cracks and/or fractured parts back to their original condition.

Types of Proprietary Services:

-

Metal stitching repair services

-

Metal surgery and reconstruction services

-

Bolt hole rebuilding and reinforcement services

-

Hybrid crack repair for high temperature and pressure vessel and pipeline.

Application for:

Cast iron crack repair, casting crack repair, gas turbine, steam turbine, wind turbine, hydro turbine, turbo-compressor, diesel engine, cylinder head, cylinder liner, reciprocating compressor, gearbox, motor, pump, compressor, generator, alternator, impeller, large gear, ball mill, kiln tire, bearing housing, valve, mould, injection moulding machine, die-casting, stamping machine.

Parent Material:

Cast iron, Cast Steel, Mild Steel, Carbon Steel, Forged Steel, Stainless Steel, Aluminum, Bronze, Brass, Aluminum Bronze, Phosphor Bronze, Ni-Resist, K-Monel, Titanium, Super Duplex, Duplex, Hastelloy, Zirconium, Inconel, Nickel-Aluminum-Bronze, Manganese, Alloy Steel, Chrome-Moly Steel, High Nickel Alloys.

Additional information:

-

Our expertise is not limited to the above, we have the expertise to carry out the crack and fracture repairs on those hardened sections caused by failed welding repairs. It is also common for us to carry out repairs on failed welding, metal locking and epoxy repairs.

-

Our repair is a permanent repair back with a 1-year standard warranty including options for extension up to 5 years.

-

Preparation of repair procedure c/w calculation for submission to relevant classification body for approval.

-

Detail job completion report.

-

Non-Destructive Testing such as magnetic particle inspection, liquid penetrant testing and/or ultrasonic testing before and after repairs.

-

Should integrated services are required for complete repair, our repair crew is equipped with portable equipment and machines comprising of portable CMM, 3D scanner, portable spray welding equipment, hydraulic drill, metal disintegration machine, portable machining machines, and laser alignment & measurement equipment.

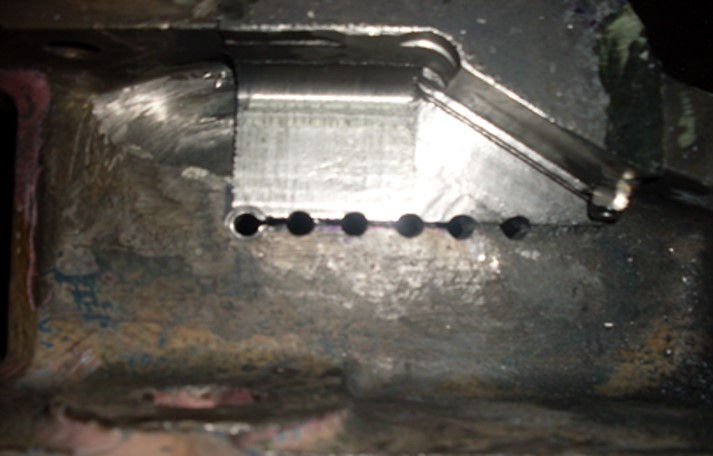

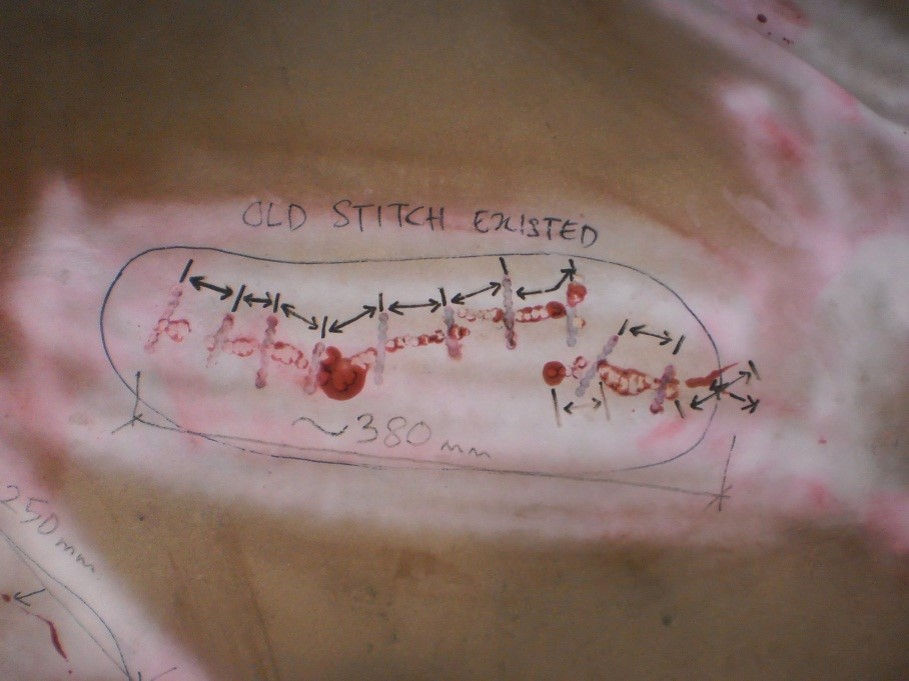

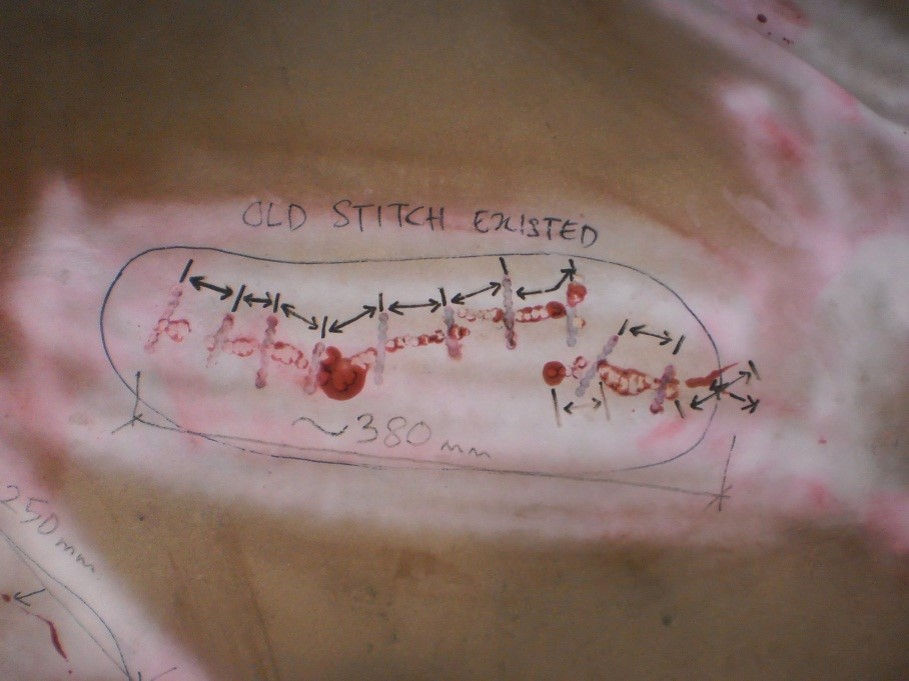

We utilized various work process and methods, including hybrid approach. Depending on the crack location and position, our repair method comprises of sole installation of stitching pins, stitching pins + locks, locks + sealing pins, reinforcement pins + stitching pins with or without inserts and other special made supports and clamps.

Engine - Oil Sump Crack

Engine - Oil Sump Crack

Metal Surgery & Reconstruction Service

Metal Surgery & Reconstruction Service

Metal Surgery & Reconstruction Service

Metal Surgery & Reconstruction Service

Bolt Hole Rebuilding & Reinforcement Services

Bolt Hole Rebuilding & Reinforcement Services

Bolt Hole Rebuilding & Reinforcement Services

Bolt Hole Rebuilding & Reinforcement Services

Hybrid Crack Repairs for High Temperature & Pressure Vessel & Pipeline - 1

Hybrid Crack Repairs for High Temperature & Pressure Vessel & Pipeline - 2

Hybrid Crack Repairs for High Temperature & Pressure Vessel & Pipeline -4

Hybrid Crack Repairs for High Temperature & Pressure Vessel & Pipeline - 1

Cast Iron Crack/Fracture Repair Services

Metal Surgery & Reconstruction Services

Bolt Hole Rebuilding & Reinforcement Services

Hybrid Crack Repairs for High Temperature & Pressure Vessel & Pipeline

"Full-Stack" Metal Surgery & Reconstruction Services

3D Scanning Services

Finite Element Analysis (FEA) Services

Laser Alignment & Measurement Services

Brush Plating/ Metal Spray Services

Portable CNC Thread Milling Services

Portable Metal Disintegration Services

Portable Machining Services

Pressure Testing Services

Types of Repair Processes

Crack Repair

Crack Repair

Crack Repair

Crack Repair

Fracture Repair

Fracture Repair

Fracture Repair

Fracture Repair

Patch Repair

Patch Repair

Patch Repair

Patch Repair

Crack Threaded Bolt Hole

Crack Threaded Bolt Hole

Crack Threaded Bolt Hole

Crack Threaded Bolt Hole

Crack Repairs

Fracture Repairs

Patch Repairs

Crack Bolt Hole Repairs

Thread Replacement Repair

Thread Replacement Repair

Thread Replacement Repair

Thread Replacement Repair

Failed Welding Repairs

Failed Welding Repairs

Failed Welding Repairs

Failed Welding Repairs

Failed Epoxy Repairs

Failed Epoxy Repairs

Failed Epoxy Repairs

Failed Epoxy Repairs

Failed Metalocking Repairs

Failed Metalocking Repairs

Failed Metalocking Repairs

Damaged Threaded Bolt Hole Repairs

Failed Welding Repairs

Failed Epoxy Repair

Failed Metalocking Repairs

Our Experiences and Expertise

Gas Turbine

Steam Turbine

Turbo Compressor

Reciprocating Compressor

Engine Frame

Cylinder Liner

Cylinder Head

Flywheel

Gearbox

Pump Housing

Bearing Housing

Valve

Blower

Ball Mill

Pump Housing (Nickel-Aluminum -Bronze)

Pump Housing (Ni-Resist)

Spiral Cooler (Stainless Steel)

Engine/Oil Sump (Aluminum)

Skid (Steel)